|

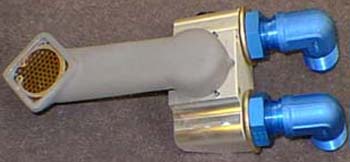

Modifications: Other Mods that can be done to the oil system: Oil screens in the intake valley. Milodon oil pan. (7 qts.) Milodon dual line oil pickup. (to be used with their pan.) Oil pressure hoses. Oil screens:  There are kits sold for Chevy's and just about any other motor BUT the AMC. So I took some freeze plugs, two sizes, punched out the centers and pressed them together with a small metal screen between. Then ream out the oil drain holes. Then press in the new drain screens. Hope to have some pictures soon. It is pretty easy to make these if you can see what I mean. I opted not to use the simple method of using epoxy to glue donw screen over the drain holes, because there is a good chance that the epoxy will not last. And the fact that the epoxy and screen will create a dam that the oil will have to build up over before it will drain down. Thus slowing the flow of oil. Side note: you can drill holes in the intake valley close to the lifter bores, but be very careful that you don't drill into the oil passages!!! Oil pan: Not much modification here. Just a great thing to have. It has all the baffles that you want. And if you get the one designed for the dual line pick, it already has the bungs for the swivel pickup. Makes for a VERY easy install. And the fact that you will increase you capacity from 5 qts to 7qts. It is a VERY nice thing to have no matter HOW you want to use your motor. Even if you will not turn high rpm's, the extra oil will help low rpm rock crawlers by keeping the motor cooler. And that is something that EVERYONE can gain from. And it is extremely useful for higher rpm usage. I am still thinking of running an external cooler for extra oil capacity, cooling, and the ease of changing the oil filters, yes two filters. Dual line pickup:  This kit consists of a swivel pickup  that mounts to the side of oil pan. (I wouldn't try this without their oil pan). A spacer that goes between the oil pump housing and the oil filter mount. that mounts to the side of oil pan. (I wouldn't try this without their oil pan). A spacer that goes between the oil pump housing and the oil filter mount.  The spacer is approx. 1" thick, so make sure that this will not cause any interference problems. The spacer is used for the second oil pickup line coming from the pickup.

The spacer is approx. 1" thick, so make sure that this will not cause any interference problems. The spacer is used for the second oil pickup line coming from the pickup.  The original oil pickup is removed and plugged off. Then you must drill and tap a hole in the block directly behind the oil pump. If you look, there is a boss, or small hole in the block about

3/4" back from the front of the block. It is almost the correct size. Just finish drilling it through. Be VERY carful!!! There is a groove in the side of the block driectly above where you

will be drilling, and if you are off, you can expose the oil passage! NOT good! Tap it to 3/4" npt, and use this for the other oil pickup line from the pickup.

The original oil pickup is removed and plugged off. Then you must drill and tap a hole in the block directly behind the oil pump. If you look, there is a boss, or small hole in the block about

3/4" back from the front of the block. It is almost the correct size. Just finish drilling it through. Be VERY carful!!! There is a groove in the side of the block driectly above where you

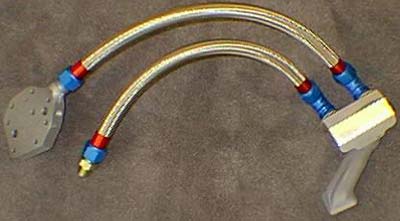

will be drilling, and if you are off, you can expose the oil passage! NOT good! Tap it to 3/4" npt, and use this for the other oil pickup line from the pickup.This kit is supposed to double the oil volume from 5-6 gpm to 10-12 gpm. And that is a BIG increase. It will help cool the motor, lubricate it when it normally wouldn't, and just keep your motor in a much safer opperating range. Oil pressure hoses: While this may seem minor, it is still a good thing to have these as precautions to hazards. I think that just about everyone has had problems one time or another with the little hose from the oil pressure sender. There is a very simple solution. If you look at small grease guns, you will noticethat the fitting are the same as the fitting needed for the sending unit. Simply use a couple of these hoses, (or get one made), that goes from ther sender to the gauge. This not only stops all leaks. But also makes a nearly indestructable setup. The fittings will not leak. The hose itself it rated to something like 3,000 psi, and I don't think that ANY one has to worry about that. And the hoses were made for petroleum products. It also allows for a worry free install through the firewall. And it is also a larger diameter that allows for more volume. This means that the oil gauge will be MUCH more accurate at lower rpms, and be more sensitive to small pressure changes. All this for a couple of dollars and a few minutes. --Back-- |